Technically, the investment casting industry has a history going back to more than 5000 years. Ancient civilisations developed castings with the lost-wax method and created idols, jewellery, weapons, ornaments, and statues too. Clay and beeswax were a few of the materials used to create the products.

As time marched on, demand grew for better investment castings because of:

- Complex design requirements

- Growth in industrial needs (travel, medical, military and many more industries required castings)

- Higher emphasis on strength, durability and dependability

And so, the investment castings journey that began in 2500 BC has included destinations like Warsaw, Indiana where Texmo Precision Castings works to make investment castings for a few of the biggest companies in the world with best-in-class processes, and materials.

Importance of ‘Material wealth’

There is an extremely specific list of qualities that materials must have. Only after a material has checked all quality criteria does it become valuable to us. Few of the qualities that we check for include:

- Strength

- Flexibility

- Malleability

- Structural integrity

- Resistance to corrosion

- Capability of being welded to other materials

- Performance when it is heat-treated

- Weight of the material etc

Currently, most investment castings company such as ours, use steels of different kinds and diverse alloys to create components and products for various industries. The choice of material and process depends on the part that is being cast and the design requirements.

Choice of materials

Our components go into a vast array of products such as joint replacement parts, flight data recorder housings, dental implants, power tools, military equipment, stents, hydraulic fluid systems, safety equipment, and surgical instruments to name just a few. Most of our castings are made from:

- Carbon steels

- Low alloy, and high alloy steels

- Tool steels

- Stainless steels

- Cobalt, and Cobalt-chrome alloys

- Nickel, and Nickel-copper alloys

Choice of materials will be made based on the use of the part as well. For instance, if we are making food & drink equipment, then we choose materials such as austenitic stainless steels which are highly resistant to corrosion. Similarly, cobalt alloys are excellent for orthopaedic implants, while nickel alloys perform well in the oil & petrol industry.

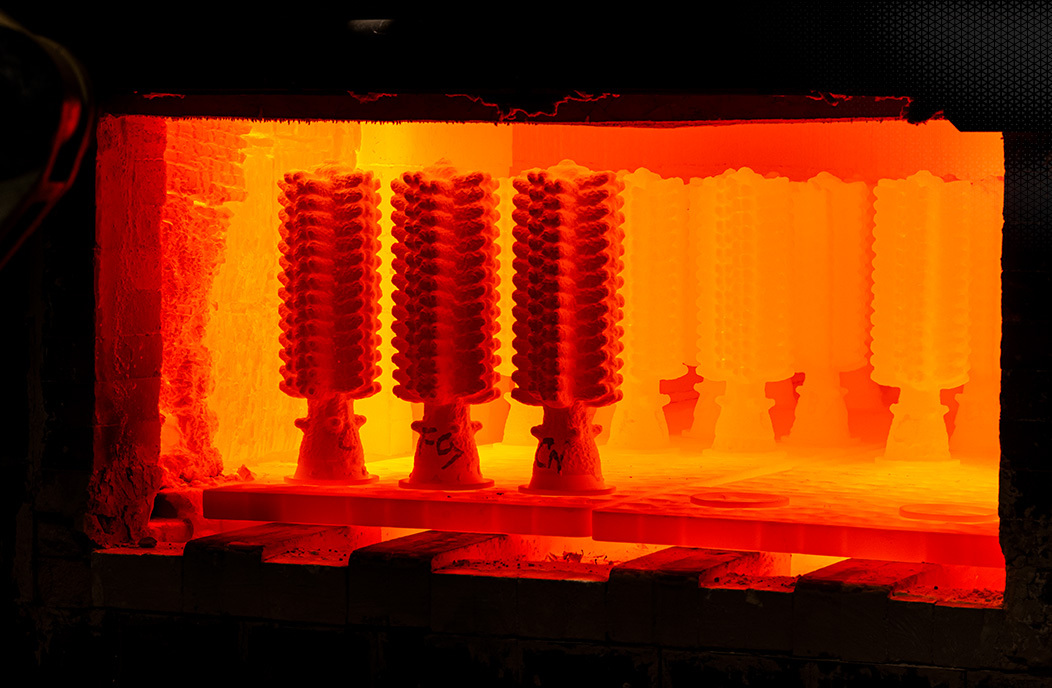

The production process helps take our metals & alloys from raw materials to finished goods. During this production process, design specifications play a huge role in creating and crafting the investment castings. It is critical to incorporate elements such as thickness of the casting, intricacy of design, undercuts, and surface finishes too.

Finally, the ‘finishing touch’ also needs the right materials. Depending on how the casting should be ‘finished’, we choose from materials such as nickel, zinc, Nitric and Hydrofluoric acids, and even high velocity oxygen fuel.

No doubt, the wealth of materials we choose from allows us to meet the precise needs of our customers so they can bank on us every single time.