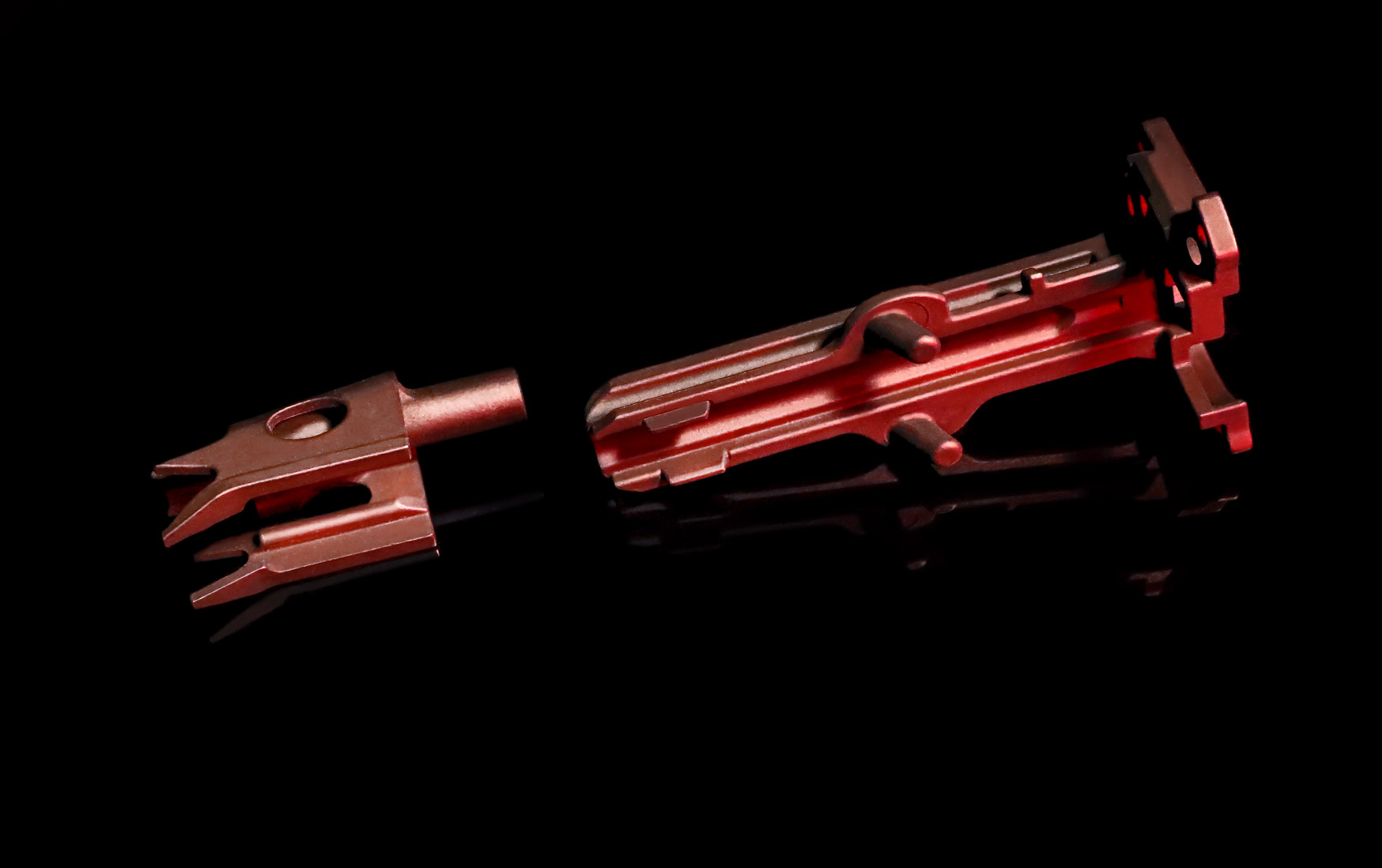

NAIL GUN

COMPONENT

FOCUS:

COMPLEX

GEOMETRY SECTIONS

THE PROBLEM

Complex geometry and dimension requirements meant that zeroing in on a manufacturing process is not easily achievable.

THE SOLUTION

Texmo’s experience with such types of components and engineering expertise meant that we were able to collaborate with our customer to first find solutions that mitigate risk, but then we were able to conduct detailed process simulations to zero in on a manufacturing process to build high quality, dimensionally accurate components.

THE IMPACT

We were able to deliver a solution to our customer and get production ready with full approvals in just 12 weeks. This ensured that our customer could transition to supply from Texmo – an urgent requirement for our customer as their current source provided inconsistent quality and supply.

CURRENT TOOLING

COSTS TOO HIGH?

To find out how Texmo Precision Castings can help you, arrange a chat with Andy Price.